Products

Catalytic Convertor

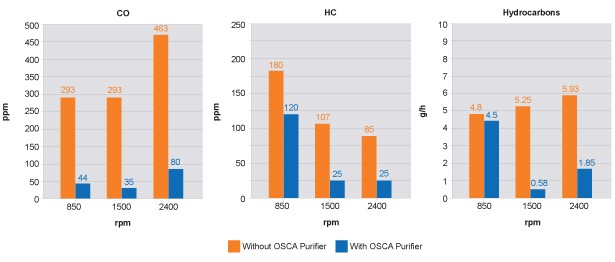

- Up to 90% reduction in pollutants

- Reduces Carbon Monoxide (CO)

- Reduces Unburned Hydrocarbons (HC)

- Effective on Aldehydes

- Suitable for any diesel engine

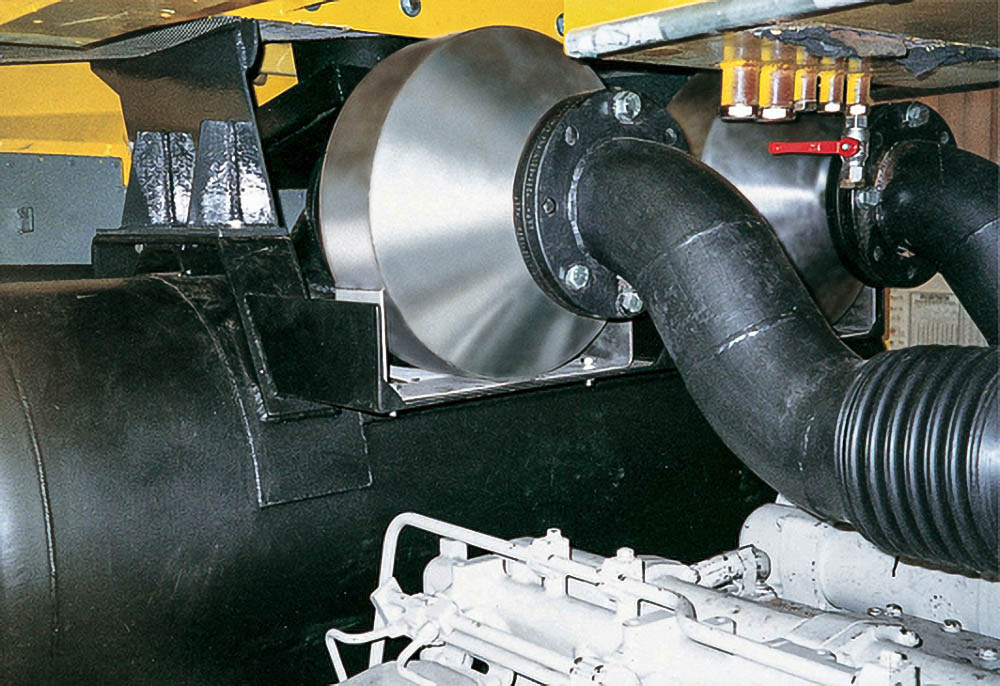

Twin catalyst application on a locomotive

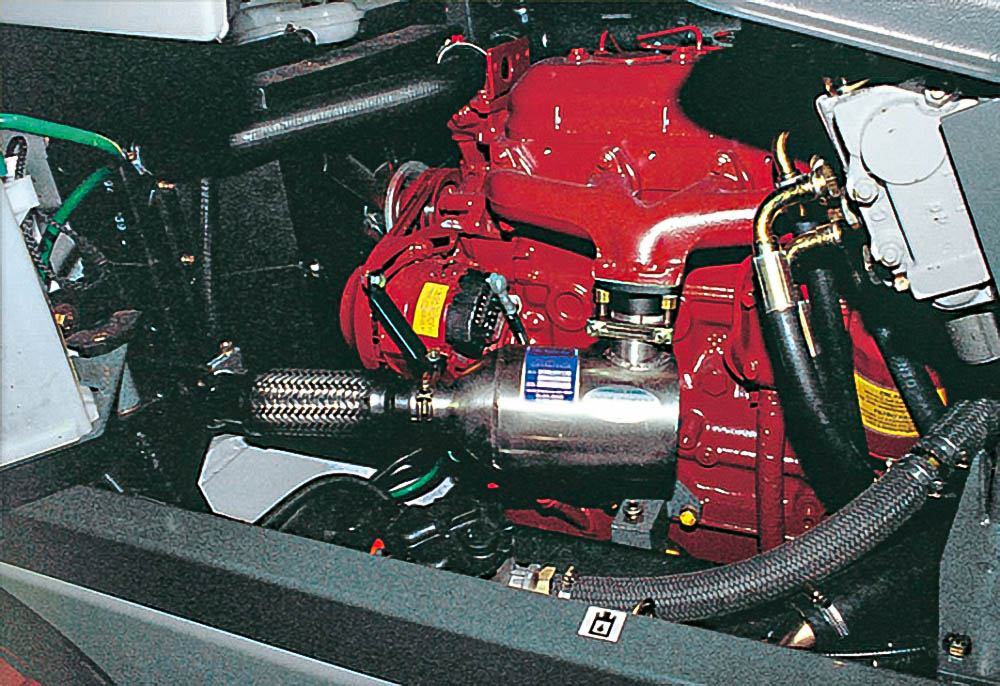

Application on a forklift truck

The OSCA Catalytic Converter uses a catalytic chemical conversion to transform carbon monoxide (CO) and unburned hydrocarbons (HC) into non-toxic carbon dioxide and water.

This conversion is carried out through a metallic honeycomb substrate coated with platinum, palladium and rhodium. The catalyst is capable of reducing up to 90% of pollutants at an optimum operating temperature of 250°C.

Applications

The catalyst is suited to any diesel engine application, such as prime power or standby generator sets, NRMM such as earth moving equipment and materials handling equipment such as forklifts and telescopic handlers. In particular the catalyst is suited to equipment being used in a confined space such as tunnels, warehouses and mines.

Installation

It is essential that fitment is as close as possible to the engine exhaust manifold, the OSCA V3NA requires high temperature to ensure maximum catalytic efficiency. There is no particular direction of flow through the catalyst and should be installed directly in the exhaust line, the original silencer system is left in place.

Maintenance

The catalyst should be cleaned every 500 hours, this is achieved by letting the catalyst cool down after use, removing the honeycomb substrate from the housing and soaking in hot soapy water for 5 hours. The catalyst can be replaced once thoroughly dry.

Life

The nature of a catalytic converter is a catalytic reaction; hence the life of the catalyst is theoretically unlimited. Due to unavoidable operating conditions such as engine vibration, poorly tuned engines and abrasive action of the exhaust, the life of the catalyst is reduced. As a result of this, the catalyst requires replacement after 10,000 hours of use.

The OSCA Catalytic Converter uses a catalytic chemical conversion to transform carbon monoxide (CO) and unburned hydrocarbons (HC) into non-toxic carbon dioxide and water.

Specifications

Select the cubic capacity (cc) range from the figures in the table below and click on the correct model for your engine. For Turbocharged engines, multiply engine cc by 1.4 and read directly from the table.

| CC | Model |

| 300 – 700 | OSCA D10 |

| 700 – 1,500 | OSCA D20F |

| 1,500 – 2,500 | OSCA D50F |

| 2,500 – 4,100 | OSCA D80F |

| 4,100 – 6,500 | OSCA D110F |

| 6,500 – 9,800 | OSCA D150F |

| 9,800 – 13,100 | OSCA D200F |

| 13,100 – 19,700 | OSCA D250F |

| 19,700 – 25,000 | OSCA D350F |

| 25,000 – 35,000 | OSCA D400F |

| 35,000 – 45,000 | OSCA D500F |

Click to open in new tab, or Right-Click to download.

Pricing and Quotations

For pricing or a written quotation, please contact us with your requirements.

Related Products

Customer Reviews

“Emissions for this set are very low, especially CO

which is very close to 0 ppm“

OSCA Catalytic Converter, applied to a Generating Set