Products

Retrofit DPF

- For stand by use and low exhaust gas temperature

- Over 99% reductions in particulate matter (PM)

- Operates from engine start-up

- Additional silencing and reduces odour

- No regeneration required, quick cartridge replacement

Exhaust gas purification is an ever evolving technology and Bersy are continually improving their range of exhaust gas purification systems in order to offer the most advanced, long lasting and reliable solutions.

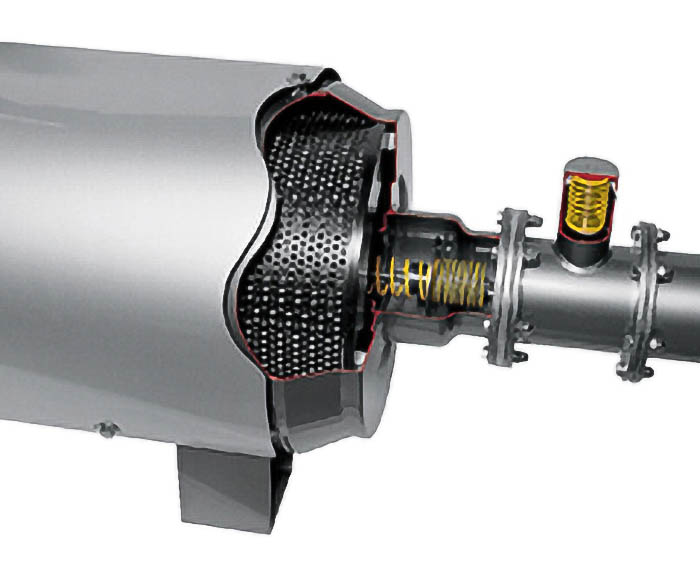

After many years of research and development into improving exhaust emissions, Bersy now presents this innovative exhaust gas filtration system. The retrofit UGET 3+ is a dry particulate filter system, capable of reducing particulate matter by over 99%. The system is designed for use in applications where the exhaust gas temperature may not reach sufficient levels for DPF regeneration, a common problem on standby generating sets. The filter also offers some silencing and removes odour from the exhaust outlet.

GenCat has ample experience on projects where generator startup smoke and odour has been an issue, particularly in the Central London area.

The environmental and health advantages are clear, enabling customers to meet the very stringent regulations laid down by Government Health and Safety executives. Therefore the UGET 3+ filter is BAFU and TRGS 554 compliant.

Operating Principle

Very fine unburnt carbon particles are responsible for the typical black smoke emitted from a diesel engine exhaust. They are the main cause of many respiratory illnesses and also have a damaging effect on the environment. These negative effects are compounded when diesel vehicles are used in confined spaces or in close proximity to human beings (i.e. tunnels, mines, quarries or in factories and warehouses).

The UGET 3+ filter housing is made of stainless steel and encompasses a heat shield for protection against burns; the filter cartridge is fire & heat resistant (to 200°C) and also resistant to aggressive elements contained in the exhaust gases.

The texture weave of the special fibres retains carbon particles as small as 20nm.

The filter system is fitted in addition to the existing exhaust system and the fibrous material of the filter element traps the carbon particles, retaining them in the filter allowing the remaining exhaust gases to pass through.

UGET 3+ filters are available in various standard sizes and are supplied complete with cartridge(s) ready for immediate use.

As well as standard models, Bersy can produce units suitable for even larger engines to suit customers’ individual needs.

Installation

Designed for simple retrofit applications, Bersy recommend that the UGET 3+ filter is fitted as far away as possible from the engine to avoid any problems with the filter overheating. The filter housing should be fitted to the vehicles frame or body with fixing brackets and connected with a piece of flexible pipe, using the counter flanges supplied, to the existing exhaust outlet.

It is advised to fit the UGET 3+ filter system after the silencer.

Fitting the pressure control kit is straightforward and is compulsory in some European countries.

Backpressure Control Kit

In order to check the efficiency of the system, an additional control system is available separately to verify the back pressure created by the filter.

Through a LED, the pressure control kit shows the operator the filter is working correctly or if any necessary maintenance is required.

Also available is the ECU BYBOX, an advanced control system to monitor temperature and pressure, storing the related data values for evaluation later.

Maintenance

The filter does not require any scheduled maintenance.

At the end of the filter cartridge life, the back plate and cartridge are removed and replaced with a new one.

Used cartridges are not classed as hazardous waste, but must be disposed of as special waste.

Bersy suggest verifying local regulations for the disposal of used cartridges.

Filter Life

The life of the filter element is approximately 250 hours of use, depending on the condition and maintenance of the engine.

Pricing and Quotations

For pricing or a written quotation, please contact us with your requirements.

Further Information

The GenCat Engineering Department have produced a White Paper describing Diesel Particulate Filter (DPF) types, technology and applications, download it now as a pdf.

“How to reduce black smoke from diesel engines – Diesel Particulate Filters”

Find out more about the London NRMM LEZ at the non-road mobile machinery site:

“London’s ‘Low Emission Zone’ for non-road mobile machinery”